Sprayer Calibration

go.ncsu.edu/readext?1106645

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲Sprayer calibration is one of the most important steps you should perform annually before the growing season. Proper maintenance and calibration of your sprayer ensures that you are applying the correct rate of product and that the spray is going to where you need, the canopy. Spray drift that misses the target wastes moneys and leads to negative environment and health effects.

Vineyard Airblast Calibration

The following is adapted from “Six Steps to Calibrate and Optimize Airblast Sprayers” by Gwen Hoheisel, WSU Regional Extension Specialist. Preform these steps annually!

Step 1 – Confirm Speed

Measure your tractor and implement speed either through manual check or a GPS tool such as a GPS mobile app. Speedometers on farm tractors may be unreliable for correct sprayer calibration and should be checked annually. When checking speed the following conditions must be met:

- Sprayer tank is half full

- Use the same tractor gear and engine speed (RPM) that you will be using for spraying,

- Power take-off (PTO) is on and fan is on

- Drive on ground surface is typical of orchard or vineyard conditions, not on gravel roads

- Run the tractor in both direction to minimize variations

Manual check

- Mark a path at least 75 feet (ft) long in a row with two flagging stakes. If the terrain is variable, use a longer path or multiple paths to increase overall accuracy.

- With a chosen gear and engine speed (RPM) combination with the PTO fan on use a stopwatch to record the time it takes for the front tire of the tractor to pass from one stake.

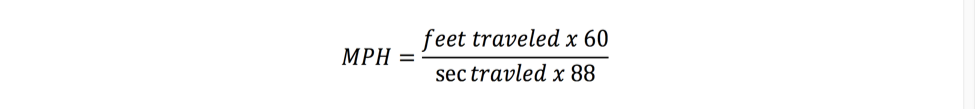

- Use the following formula to calculate tractor speed.

Use a tool

There are many GPS technologies such as GPS receivers or phone applications that are available in common electronic devices that can give an accurate assessment of speed. To better measure the travel speed, follow these steps:

- Start the GPS tool.

- Set your gear and engine speed (RPM) with the PTO and fan on.

- Drive down a row for 30 seconds and look at the travel speed.

- To obtain desired speed, change gear or throttle combinations. Each time allow 30 seconds to acquire a stable reading on the GPS tool.

Step 2 – Adjust Air Direction

Adjusting the Air Direction adjusts where the spray droplets: “Wherever air goes, droplets follow.” You can control where spray enters the airflow by adjusting nozzle orientation or selecting nozzles that directly spray the canopy. To determine air direction follow these steps:

- Park the sprayer in a row.

- Tie a two-foot piece of flagging tape to the nozzle bodies.

- Make sure your nozzles are turned off. Turn on the sprayer, engage the tractor PTO and fan, and adjust the RPM used for spraying.

- Note the orientation of the flagging tape as the sprayer air is on. Notice which flagging tape is directed into the canopy. Use only those nozzles that have the flagging tape oriented directly into the canopy and those slightly over the top and under the bottom of the canopy. Any nozzles not within that range should be turned off.

- Turn on sprayer nozzles (water only) and visually see where the spray goes. Note any sprayer orientation, if possible, that can be adjusted. Once the water is off, adjust and turn on again to reevaluate.

- Record number of nozzles needed and placements for each side.

Step 3 – Air Volume Adjustment

Match the Air Volume and Speed to the Canopy. The volume of air coming from the sprayer should allow the spray to penetrate the canopy but not carry beyond the other side. Wind, canopy density, and tractor speed will affect the volume of air displaced by the sprayer. The directions below for determining the air volume should be followed throughout the season when canopy volume changes. Such as budbreak, bloom, and veriason.

Note: Air-shear nozzles (such as CIMA) cannot adjust air volume as they require a an RPM speed of 540 to provide consistent spray droplets.

- Tie ribbon to the top, middle, and bottom shoots of the far side of the canopy from where the sprayer is driving.

- Drive by using sprayer settings established in the previous steps. Have a person stand at the end of the row to watch flagging tape.

- The goal is to have the ribbons on the outside of the canopy from where the sprayer passes to lightly flutter. If ribbons blow straight out, reduce air by reducing fan gear from high to low, drive faster, or change the tractor settings to gear up and throttle down. If the ribbon doesn’t move, increase air by driving slower, increasing rpm, or fan gear.

Note on Reducing Air Volume

Some sprayers have a gear to adjust fan speed. Reducing the fan speed to low is easy and will create less air volume. Some sprayers may have fixed fan speed, but there could be the option of installing a smaller fan or changing the pitch of the blades.

You could “Gear Up, Throttle Down” method, where the tractor is placed in a higher gear to maintain travel speed while throttled down (i.e., slow the PTO) to reduce the fan RPM. A reduction in RPM means the fan spins slower and produces less air volume. This method does have caveats. There can be problems on hills where the tractor may not have enough power to climb and maintain speed. Sprayers with centrifugal pumps, once pressure drops, GPM per nozzle drops, thus there will be a need to recalibrate.

Step 4 – Nozzle Selection

In step 2, you determined the correct location and amount of nozzles, now you need to select the type of nozzle for your desired output. To select nozzles for your desired output, two standard measurements are needed: gallons per acre (GPA) describes the sprayer output and gallon per minute (GPM) determines the nozzle output. Use the following steps or software to calculate the total expected output from each nozzle and suggest the proper nozzle.

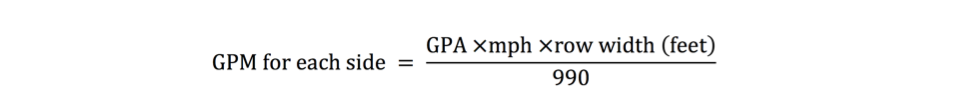

- GPA is determined by your ground speed, row width, nozzle selection, and operating pressure. To calculate the gallons per minute per side (GPMS).

- If the expected output from every nozzle on one side is the same, divide the GPMS by the number of nozzles on a side (i.e., GPMS ÷ number of nozzles per side = output per nozzle). Vineyard GPMS will be proportional, and each nozzle output can be equal.

- All nozzles are rated to deliver a specific GPM under a certain operating pressure (measured in pounds per square inch, or PSI). To select nozzles with the expected output in GPM for each nozzle, use a nozzle catalog to find a nozzle output that is close to the calculated output. In general, nozzles with a hollow-cone spray pattern are used to spray the canopy of fruit crops. Ceramic is always preferred as it wears less. Make sure discs and cores are of the same material. Several options of nozzles and materials are available.

The desired sprayer output (e.g., 100 GPA) is achieved when you match your speed, pressure, and nozzle output. To do this, you will need to know the running pressure in PSI and the desired GPA.

Step 5 – Confirm Nozzle Output

Measuring nozzle output should be conducted at least once before the season begins and any time during season to assess nozzle wear. Alternately, to skip this step, replace interchangeable nozzles before every season and confirm pressure gauge works correctly.

- Confirm the pressure gauge is at the correct PSI (pressure gauge should be replaced or calibrated annually).

- Connect hose to the nozzles. Clamps can be used to securely attach hose to nozzle and collect all spray.

- Turn on sprayer with no air, collect output for 60 seconds into an ounces measurement, measure and calculate to gallon to give you GPM per nozzle. Alternatively, a flow meter could be used to collect output in GPM and eliminates the math.

- Any nozzle that is more than 10% off from expected should be replaced. Replace ALL nozzles if more than 2 are bad.

Step 6. Verify Coverage

The final step is to confirm the spray coverage with water sensitive paper (WSP). WSP is yellow paper that turns blue with water droplets, allowing you to visualize the spray coverage. When working with WSP, always wear nitrile gloves as the moisture in your hands turns the card blue, and use when there is low humidity.

WSP can be place in the fruit zone and throughout the canopy to confirm the spray is going to where desired. Attach WSP by stapling to leaves directly or securing with metal clips. To evaluate drift, you can attach WSP to small wood block and place on the ground one to three rows downwind.

Operate the sprayer at the settings determined from the previous steps and drive past the canopies with the WSP (assess coverage using water only in the tank). Depending on weather, allow at least 10 min for the spray to dry on cards, then collect them and examine the coverage. In general, ideal spray coverage has many fine droplets evenly covering the card without long streaks or large patches of solid blue.

Boom Sprayers and Spreaders

It doesn’t matter the type of sprayer, they should be calibrated annually. Read more on boom sprayers and spreaders calibration.